Guest post by Lynette Farinas, Nvidia—

Flight and robotics have always been Marc Gyongyosi’s biggest passions. At age 15, he built a flight simulator modeled after a Boeing 737. Four years later, he joined BMW’s Advanced Robotics R&D department in Munich.

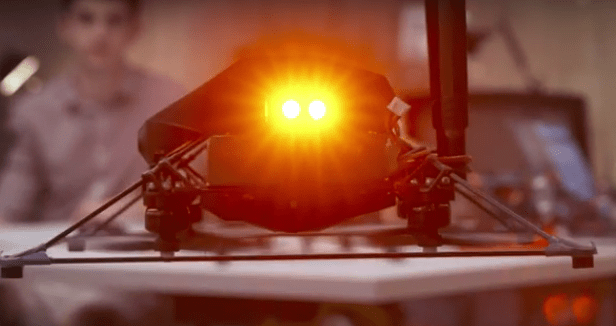

Now the college senior is founder of a startup, IFM, that’s developed a Jetson-powered autonomous drone. The company first unveiled its indoor navigation technology at NVIDIA’s GPU Technology Conference in April, and is now staking a claim in the $5 billion warehouse analytics industry.

Flying Robots and the Great Indoors

IFM has come a long way in the short time since Gyongyosi founded the company in 2014. While pursuing a computer science degree from Northwestern University, he saw the immense potential for drones — flying robots, as he calls them — that could find their way around indoor spaces like factories and construction sites. Since GPS doesn’t work indoors, he had to devise an alternative navigation system.

Gyongyosi, along with two Ph.D. candidates, Siddarth Jain and Nathan Matsuda, set out to solve this problem. The team designed an indoor positioning system based on a single camera, Vision-SLAM, and sensor fusion algorithms, all running on a Jetson TK1 Developer Kit. Then they built a quadrotor drone to take the system airborne. Live demos of the early prototype wowed GTC audiences by flying around an indoor warehouse environment.

But that was months ago. In startup land, things move fast and the stakes get bigger by the day.

After exploring the market for drones, and extensively testing IFM’s technology in different applications, they made the decision to focus on warehouse analytics for their first commercial product. There are hundreds of thousands of these warehouses in the United States alone and they’re overflowing with goods.

Locating a specific product, let alone counting them all, is no easy task for workers. Yearly inventory and bi-weekly cycle counts lead to lost revenue because warehouses need to be closed and items painstakingly counted. And even then, 100 percent accuracy is never guaranteed.

“We’re the first to offer a fully autonomous, end-to-end inventory checking solution for warehouses,” Gyongyosi says. “While we eliminate the need for a manual inventory counting task, this doesn’t take the place of people. Instead we make day-to-day operations easier and more productive for everyone in these warehouses. We want IFM’s solution to be a tool for warehouse workers.”

To achieve this, IFM has built a new drone around the newer, more powerful Jetson TX1 supercomputer.

“This is a completely new prototype with an incredibly small form factor carrying TX1,” Gyongyosi explains. “With the resources provided by NVIDIA, we developed our own electronics around the TX1 module and re-engineered the flying robot from the ground up to optimize for performance.”

And it worked: IFM’s new drone has more than 20 minutes of flight time, only weighs 1 kilogram and can identify a standard pallet on either side at a distance of up to 2.5 meters. In other words, it’s small, light and agile enough to zip through the corridors and tight spaces of a warehouse. And it’s smart enough to accurately track inventory in the process using IFM’s computer vision software.

“We’ve seen a 6x increase in tracking rate since upgrading to TX1. With TX1, we got smaller and lighter, and increased performance,” Gyongyosi said. “That’s the best thing that can happen.”

Taking Off From Northwestern’s Garage

Since the summer of 2015, the startup has been working out of The Garage, a Northwestern University-hosted incubator run by ex-Googler Melissa Crounse. Built on the second floor of a parking garage, the aptly named space has plenty of room for flight tests and ample access to university-sponsored events and resources.

Gyongyosi credits the space and support The Garage offers with helping IFM grow to where it is now: A cutting-edge company with a second-gen prototype up and running, and pilot partners across automotive manufacturing, industrial supplies, and food and beverage distribution.

Bigelow Tea, which is the No. 1 specialty tea company in the country and makes 1.7 billion tea bags per year, is one such pilot partner. “I was at Northwestern’s Garage when I first saw IFM’s drone,” said Cindi Bigelow, president and CEO of Bigelow Tea. “Halfway through Marc’s explanation, I knew this had enormous potential to help our organization and immediately wanted us to become a beta site.”

“During our busy season, which is six months out of the year, our warehouses are packed. Counting and identifying products can take hours and be very frustrating,” Bigelow said. “IFM’s drone can help make our employees’ experiences better, more enjoyable and give us the opportunity to serve our customers better.”

And the sky’s the limit for this startup. Warehouses are vital to many industries’ operations, and billions of dollars are lost each year to inventory errors and the sheer time and effort it takes for people to climb ladders, drive forklifts and otherwise track down missing goods.

As Gyongyosi put it, “Humans prefer counting things when they want to fall asleep, and not at work.” Building smart machines to help with the counting is IFM’s mission.

Unmanned Aerial Vehicle The latest drone news

Unmanned Aerial Vehicle The latest drone news